Electric Vehicle Component Shortages: Semiconductor Crisis and Production Delays

Electric vehicle component shortages, particularly semiconductors, continue to significantly impact the automotive industry, leading to production delays and increased wait times for consumers eager to embrace electric mobility.

The automotive industry, particularly the electric vehicle (EV) sector, is currently grappling with significant electric vehicle component shortages. The persistent semiconductor crisis is a major contributor, causing production bottlenecks and delivery delays. Understanding the multifaceted impact of this shortage is crucial for consumers, manufacturers, and investors alike.

Understanding the Electric Vehicle Component Shortage

The electric vehicle (EV) industry is rapidly expanding, but this growth is being hampered by numerous supply chain challenges. Shortages of important components, particularly semiconductors, are creating considerable obstacles for EV manufacturers.

The Role of Semiconductors in Electric Vehicles

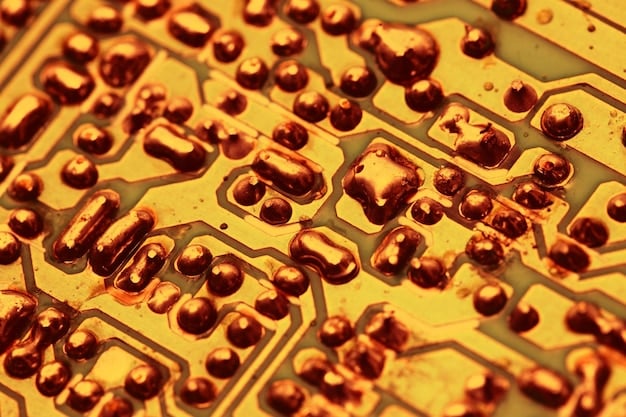

Semiconductors are essential for various functions in EVs, from battery management systems to infotainment systems and advanced driver-assistance systems (ADAS). Without an adequate supply of these chips, EV production is severely hampered.

Global Factors Contributing to the Shortage

- Increased Demand: The rising popularity of EVs has significantly increased the demand for semiconductors.

- Supply Chain Disruptions: Global events such as the COVID-19 pandemic and geopolitical tensions have disrupted the semiconductor supply chain.

- Manufacturing Capacity: Limited manufacturing capacity and long lead times for new chip production facilities exacerbate the shortage.

The convergence of these factors has created a perfect storm, making it difficult for EV manufacturers to secure the components they need to meet production targets. This shortage is not just a minor inconvenience; it has far-reaching effects on the entire EV ecosystem.

In conclusion, the electric vehicle component shortage is a complex issue influenced by many factors. Addressing this shortage requires coordinated efforts from governments, manufacturers, and suppliers. This is essential to ensure the continued growth and success of the EV industry.

The Impact on Electric Vehicle Production

The shortage of components, especially semiconductors, significantly impacts the production capabilities of electric vehicle manufacturers. Production lines have slowed down, and in some cases, have even been temporarily halted, because of the shortage.

Production Slowdowns and Factory Closures

Many EV manufacturers have been forced to reduce their production output due to the lack of essential components. In some instances, factories have had to temporarily close as they await shipments of semiconductors and other critical parts.

Delivery Delays for Consumers

Consumers eager to purchase electric vehicles are experiencing extended wait times. The inability of manufacturers to meet demand means that delivery times for new EVs have increased significantly which causes frustration among customers eager to switch to EVs.

- Longer Wait Times: Order fulfillment for new EVs can take several months, with some deliveries delayed by a year or more.

- Price Increases: Component shortages can lead to higher production costs, which are often passed on to consumers through increased vehicle prices.

- Reduced Model Availability: Some manufacturers have reduced the availability of certain models or configurations due to the scarcity of components.

Delivery delays are not only frustrating for consumers but also impact the overall adoption rate of electric vehicles. Uncertainty around delivery times may deter potential buyers, slowing down the transition to electric mobility.

In summary, the component shortage is having a tangible impact on EV production and consumer experiences. Addressing these challenges is critical to maintaining the momentum of the EV revolution.

Semiconductor Shortage: A Deeper Dive

The semiconductor shortage is at the heart of the electric vehicle component shortage issue. Understanding the reasons behind this shortage and its specific impact on the EV industry is vital for developing effective solutions.

Why Semiconductors Are Crucial for EVs

Electric vehicles rely heavily on semiconductors for a wide range of functions, including battery management, power electronics, motor control, and infotainment systems. The increasing sophistication of EVs means they require even more advanced chips than traditional vehicles. The integration of advanced driver-assistance systems (ADAS) and autonomous driving technologies further increases semiconductor demand.

Factors Exacerbating the Semiconductor Shortage

Several factors have contributed to the ongoing semiconductor shortage.

- Geopolitical Tensions: Trade disputes and geopolitical instability have disrupted the flow of semiconductors across borders.

- Increased Demand from Other Sectors: The semiconductor shortage is not unique to the automotive industry. Other sectors, such as consumer electronics and telecommunications, are also experiencing high demand for chips.

- Lack of Investment in Manufacturing Capacity: Insufficient investment in new semiconductor manufacturing facilities has constrained the overall supply of chips.

The semiconductor shortage is a multifaceted problem with no quick fix. Addressing this challenge requires significant investment, international cooperation, and innovative solutions to increase chip production and optimize supply chains. This is necessary to maintain production in the growing EV marketplace.

Strategies to Mitigate Component Shortages

Electric vehicle manufacturers must develop and implement effective strategies to mitigate the impact of component shortages. Proactive measures can help ensure a more stable supply chain and minimize disruptions to production.

Diversifying the Supply Chain

Relying on a single supplier for critical components can leave manufacturers vulnerable to shortages. Diversifying the supply chain by sourcing components from multiple suppliers reduces the risk of disruptions.

Building Strategic Partnerships

Establishing close relationships with semiconductor manufacturers and other key suppliers can help secure a more reliable supply of components. Strategic partnerships can also facilitate better forecasting and coordination.

Investing in In-House Chip Design

Some EV manufacturers are exploring the possibility of designing their own chips. This approach gives them greater control over the supply chain and allows them to tailor chips to their specific needs. While this requires substantial investment and expertise, it can provide a competitive advantage in the long run.

Successfully navigating component shortages requires a mix of strategic partnerships, supply chain diversification, and technological innovation. By taking proactive measures, EV manufacturers can minimize disruptions and maintain a competitive edge in the rapidly evolving market.

The Long-Term Outlook for Component Availability

The long-term outlook for component availability in the electric vehicle industry is uncertain, but several trends and developments suggest that the situation will eventually improve. It is important to try to plan effectively for the present and future by monitoring the market and having different action plans to use as necesary.

Increased Investment in Semiconductor Manufacturing

Governments and private companies are investing heavily in new semiconductor manufacturing facilities. These investments will gradually increase the global supply of chips and alleviate the shortage over time.

Technological Advancements in Chip Design

Innovations in chip design are making it possible to produce more powerful and efficient chips with fewer resources. These technological advances can help reduce demand for scarce components and improve overall efficiency.

Policy and Regulatory Support

Governments are implementing policies to support the semiconductor industry and promote domestic chip production. These policies can help ensure a more stable and secure supply of components for the electric vehicle industry.

While challenges remain, the long-term outlook for component availability is cautiously optimistic. Increased investment, technological advancements, and supportive policies are expected to improve the situation.

How Consumers Can Navigate the Shortages

Consumers interested in purchasing electric vehicles can take several steps to navigate the current component shortages and minimize potential delays.

Planning Ahead and Ordering Early

Given the long lead times for EV deliveries, it is essential to plan ahead and place orders well in advance. Ordering early increases the chances of receiving the vehicle within a reasonable timeframe.

Staying Informed About Delivery Timelines

Consumers should stay in close contact with their dealers to monitor delivery timelines and receive updates on the availability of specific models and configurations. Being informed helps manage expectations and make informed decisions.

Considering Alternative Models or Brands

If a specific model or brand is experiencing significant delays, consumers may want to consider alternative options. Exploring different EVs can lead to discovering vehicles that meet their needs and are readily available.

Navigating the component shortages requires patience, planning, and flexibility. By staying informed and considering alternative options, consumers can successfully make the transition to electric mobility despite the challenges.

| Key Point | Brief Description |

|---|---|

| 📉 Component Shortages | Semiconductor shortages impact EV production and consumer delivery times. |

| ⏳ Delivery Delays | Consumers face extended wait times for new EV deliveries. |

| 💡 Strategic Partnerships | EV manufacturers should build partnerships to secure component supply. |

| 🛡️ Supply Chain Diversification | Diversifying the supply chain reduces the risk of disruptions. |

FAQ

▼

The main reason is the semiconductor shortage, worsened by geopolitical tensions, increased demand, and limited production capacity. Also, supply chain issues worsen the problem.

▼

Experts predict that the semiconductor shortage could persist for some time, potentially easing gradually over the next few years as new manufacturing facilities come online.

▼

EV manufacturers can diversify their supply chains, build strategic partnerships, and invest in in-house chip design to secure a more reliable supply of components.

▼

Consumers can plan ahead and order early, stay informed about delivery timelines, and consider alternative models or brands to minimize potential delays in receiving their EVs.

▼

The long-term outlook is cautiously optimistic, with increased investment in semiconductor manufacturing, technological advancements in chip design, and supportive government policies expected to improve the situation.

Conclusion

The electric vehicle component shortages, particularly the semiconductor crisis, pose a significant challenge to the EV industry. Addressing these challenges requires proactive strategies from manufacturers and informed decisions from consumers. While the road may be bumpy, the long-term outlook for electric mobility remains bright.