Electric Vehicle Component Shortages: Semiconductor Crisis and Production Delays

Electric vehicle (EV) component shortages, particularly semiconductors, continue to significantly impact EV production, leading to anticipated delays in vehicle deliveries and increased waiting times for consumers in the US.

The automotive industry, including electric vehicle (EV) manufacturers, is grappling with significant electric vehicle component shortages: semiconductor shortage continues to impact electric vehicle production – expect delays. This scarcity primarily affects the production of EVs, causing delays and impacting consumers in the US market. Understanding the roots and impacts of these shortages is crucial for both industry stakeholders and potential EV buyers.

Understanding the Global Semiconductor Shortage and Its Impact

The global semiconductor shortage has become a significant bottleneck for various industries, and electric vehicles (EVs) are no exception. This shortage stems from a confluence of factors, including increased demand, supply chain disruptions, and geopolitical tensions. Understanding these factors is essential to grasping the full scope of the issue.

Factors Contributing to the Shortage

Several key elements have fueled the semiconductor shortage. Increased demand for electronics during the pandemic, coupled with supply chain disruptions, led to a strain on production capacity. Geopolitical factors, such as trade tensions and export restrictions, have further exacerbated the situation.

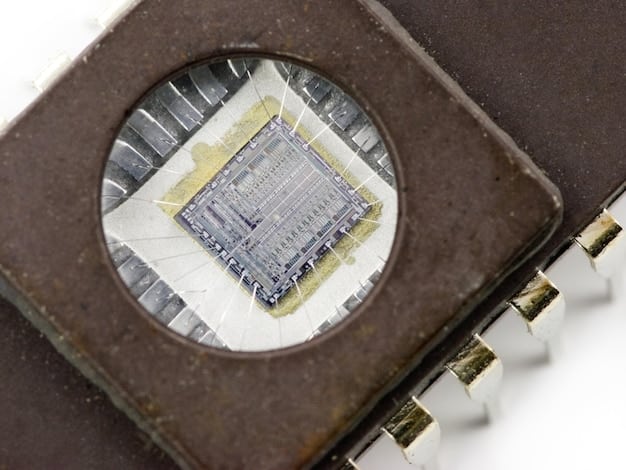

How Semiconductors Are Used in EVs

Semiconductors are integral to the functionality of electric vehicles. They power everything from the vehicle’s control systems and battery management to infotainment systems and advanced driver-assistance systems (ADAS). Without a steady supply of semiconductors, EV production grinds to a halt.

Here are some critical applications where semiconductors are used:

- Battery Management Systems: Regulating charging and discharge rates for optimal performance.

- Power Electronics: Converting DC power to AC for the motor and managing energy flow.

- Infotainment Systems: Providing navigation, entertainment, and connectivity features.

- Advanced Driver-Assistance Systems (ADAS): Enabling features like adaptive cruise control and lane-keeping assist.

In conclusion, the global semiconductor shortage has far-reaching implications for electric vehicle production, underscoring the critical role these components play in modern automotive technology.

Production Delays and Their Consequences for EV Manufacturers

The semiconductor shortage has directly translated into production delays for EV manufacturers across the globe. Factories have been forced to slow down or even halt production lines, leading to fewer vehicles being produced and longer wait times for consumers. This disruption has significant consequences for manufacturers’ bottom lines and their ability to meet growing demand.

Impact on Production Timelines

Production timelines have been severely affected, with some manufacturers reporting delays of several months. This not only frustrates consumers but also impacts the manufacturers’ ability to compete in the rapidly expanding EV market.

Financial Implications for Companies

The financial implications of these delays are substantial. Reduced production volumes translate to lower sales revenues. Additionally, companies may incur extra costs related to managing supply chain disruptions and finding alternative sources for semiconductors.

The impact extends to strategic planning and investment decisions:

- Reduced Revenue: Lower production leads to fewer sales and decreased income.

- Increased Costs: Sourcing alternative components can be expensive.

- Market Share Erosion: Competitors with more stable supply chains gain an advantage.

Overall, production delays caused by component shortages pose a significant financial threat to EV manufacturers, impacting profits, growth, and competitive positioning.

Consumer Impact: Waiting Times and Rising Prices

Consumers in the US market are feeling the direct effects of electric vehicle component shortages. The most immediate impact is longer waiting times for vehicle deliveries. Additionally, some manufacturers have been forced to increase prices, either due to higher production costs or to manage demand amid limited supply.

Increased Waiting Times for Deliveries

Prospective EV buyers are facing extended waiting times, sometimes stretching several months or even a year. This can be a major deterrent for those eager to switch to electric vehicles, leading some consumers to reconsider their purchase decisions.

Potential Price Increases for Electric Vehicles

With limited supply and high demand, some EV manufacturers have raised prices. This price inflation makes EVs less accessible to a wider range of consumers, potentially slowing down the overall adoption of electric vehicles.

Consumer Sentiment and Purchase Decisions

Consumer sentiment is also affected by the ongoing shortages. Uncertainty about delivery times and potential price increases can lead to frustration and hesitation among potential buyers. This could temper the enthusiasm for EVs and affect the long-term growth of the market.

Here’s how it affects the average consumer:

- Affordability: Price increases can put EVs out of reach for some buyers.

- Patience: Long waiting times may deter some from purchasing EVs.

- Expectations: Unmet demand can lead to disappointment and lost sales.

In conclusion, the consumer impact of EV component shortages is significant, affecting waiting times, prices, and overall sentiment toward electric vehicle purchases.

Strategies for Mitigating Component Shortages

To address the ongoing component shortages, EV manufacturers are exploring various strategies to mitigate the impact. These strategies range from diversifying supply chains to forming strategic partnerships and investing in alternative technologies. Addressing these challenges requires a multifaceted approach.

Diversifying Supply Chains

One of the most effective strategies is to diversify supply chains. By sourcing components from multiple suppliers and different regions, manufacturers can reduce their reliance on any single point of failure. This approach can help maintain a more stable supply of critical components.

Strategic Partnerships with Semiconductor Manufacturers

Forming strategic partnerships with semiconductor manufacturers is another viable solution. By securing long-term supply agreements and collaborating on technology development, EV manufacturers can gain priority access to critical components and ensure a more reliable supply chain.

Investing in Alternative Technologies

Manufacturers are also investing in alternative technologies and materials that can reduce the reliance on scarce components. This includes exploring different chip designs and innovative materials that can serve as substitutes for traditional semiconductors.

Here are some strategies being adopted:

- Reshoring: Bringing manufacturing back to domestic markets to reduce reliance on foreign suppliers.

- Inventory Management: Stockpiling critical components to buffer against supply disruptions.

- Technology Substitution: Finding alternative components or technologies to reduce demand for scarce items.

In summary, mitigating component shortages requires a combination of strategic supply chain management, partnerships, and investments in alternative technologies to ensure a more resilient and reliable EV production process.

The Role of Government Policies and Incentives

Government policies and incentives play a crucial role in supporting the electric vehicle industry amid component shortages. Policies that promote domestic semiconductor production, provide financial incentives, and support research and development can help alleviate the impact of these shortages. Supportive government action is essential for the long-term growth of the EV market.

Policies Promoting Domestic Semiconductor Production

Government policies that encourage domestic semiconductor production can help reduce reliance on foreign suppliers and ensure a more secure supply of critical components. This includes providing tax incentives, subsidies, and other forms of support for chip manufacturers.

Financial Incentives for Manufacturers and Consumers

Financial incentives can help offset the increased costs associated with component shortages. These incentives can take the form of tax credits, grants, and rebates for both EV manufacturers and consumers, making EVs more affordable and supporting production efforts.

Supporting Research and Development

Government support for research and development is critical for driving innovation and finding alternative technologies that can reduce the reliance on scarce components. This includes funding research into new materials, chip designs, and manufacturing processes.

Here are some policy actions that can make a difference:

- Supply Chain Resilience: Policies aimed at strengthening and diversifying supply chains.

- Technology Innovation: Funding for research into alternative components and technologies.

- Workforce Development: Training programs to support the growing semiconductor industry.

In conclusion, government policies and incentives are crucial for supporting the electric vehicle industry during component shortages, fostering domestic production, and driving innovation in alternative technologies.

Future Outlook: When Will the Shortages End?

Predicting the exact timeline for the end of component shortages remains a challenge, but industry experts anticipate that improvements may be seen in the coming years. Factors such as increased production capacity, easing of supply chain disruptions, and geopolitical stability will play a key role in determining when the shortages will abate. Long-term strategies are essential for ensuring a more stable and resilient supply chain.

Expert Predictions and Industry Projections

Industry analysts predict that semiconductor supply will gradually improve as new production facilities come online and existing manufacturers increase capacity. However, it may take several years before supply fully meets demand, meaning shortagesCould persist in the short to medium term.

Long-Term Strategies for a More Resilient Supply Chain

To ensure a more resilient supply chain in the long term, EV manufacturers and governments must invest in strategic partnerships, domestic production, and alternative technologies. These measures will help reduce the vulnerability to future disruptions and ensure a more stable supply of critical components.

Potential Innovations and Technological Advancements

Technological advancements and innovations in chip design and manufacturing could also play a role in alleviating component shortages. Developing alternative materials and more efficient chip designs can reduce the demand for scarce resources and improve overall supply chain resilience.

Key factors that will influence the future:

- Investment in Capacity: Ongoing investments in new semiconductor manufacturing plants.

- Geopolitical Stability: Reduced trade tensions and more stable international relations.

- Technological Breakthroughs: Innovations that reduce the need for scarce components.

In short, while predicting the exact end of component shortages remains uncertain, strategic investments, policy support, and technological advancements will pave the way for a more stable and resilient electric vehicle industry.

| Key Point | Brief Description |

|---|---|

| ⚠️ Semiconductor Shortage | Global shortage impacts EV production, causing delays. |

| ⏳ Production Delays | EV manufacturers face slowdowns, affecting delivery times. |

| 💰 Consumer Impact | Longer waits and potential price increases for EVs. |

| 🛡️ Mitigation Strategies | Diversifying supply chains and forming partnerships. |

FAQ

▼

The shortage is due to increased demand for electronics, supply chain disruptions, and geopolitical factors affecting production and distribution of semiconductors.

▼

Experts predict shortages may persist for the next few years, with gradual improvements expected as production capacity increases and supply chains stabilize.

▼

Manufacturers can diversify supply chains, form partnerships with semiconductor companies, and invest in alternative technologies to reduce reliance on scarce components.

▼

Consumers face longer waiting times for EV deliveries and potential price increases due to limited supply and increased production costs affecting the current market.

▼

Governments can support domestic semiconductor production, offer financial incentives, and fund research and development to foster innovation to mitigate effects.

Conclusion

In conclusion, the electric vehicle component shortages: semiconductor shortage continues to impact electric vehicle production – expect delays is a significant challenge for the EV industry, affecting manufacturers, consumers, and the overall growth of this sector. Strategic mitigation efforts, supportive government policies, and technology innovations are indispensable for creating a resilient and stable supply chain to ensure robust expansion.