Impact of supply chain changes on car prices

The impact of supply chain changes on car prices stems from disruptions that lead to material shortages, increased manufacturing costs, and fluctuating transportation expenses, all affecting final vehicle pricing.

The impact of supply chain changes on car prices is a vital topic for both buyers and industry insiders. Have you noticed how fluctuations in supply can alter what you pay for a vehicle? In this article, we’ll dive into the reasons behind these price shifts and what it means for your next car purchase.

Understanding the supply chain in the auto industry

Understanding the supply chain in the auto industry is crucial for grasping how cars reach consumers. This complex network consists of various stages, from raw materials to the final sale. It’s fascinating to see how pieces fit together to create the cars we drive every day.

Key Components of the Supply Chain

Each part of the supply chain plays a significant role:

- Raw Materials: Essential materials, like steel and rubber, are sourced to create vehicles.

- Manufacturing: Factories assemble components into finished cars.

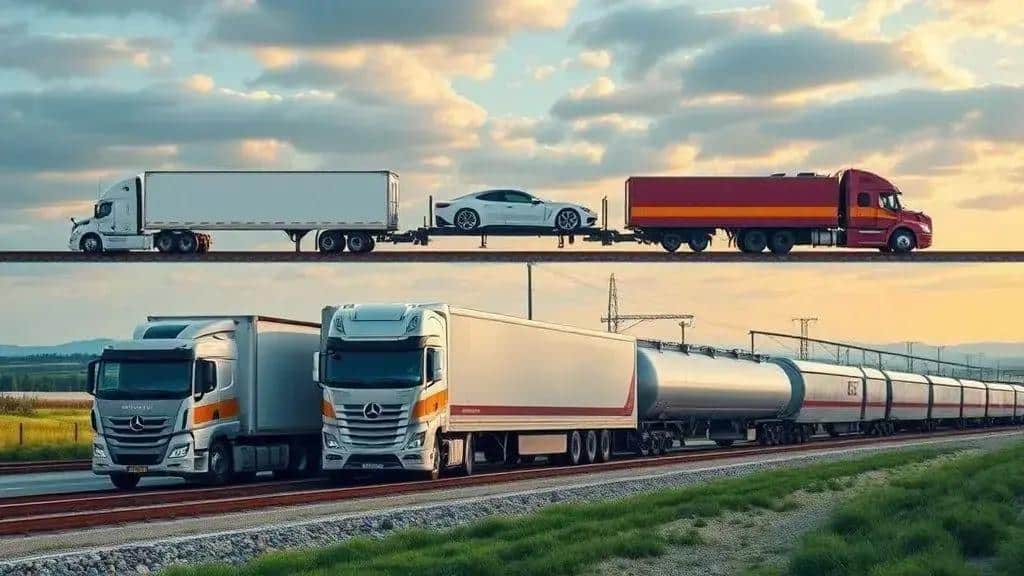

- Distribution: Vehicles are transported from manufacturers to dealerships.

- Sales: Finally, cars are sold to consumers at dealerships.

All these elements must work together smoothly. If one part experiences a delay, it can impact the entire system. For example, during the COVID-19 pandemic, many automakers faced shortages of basic parts, leading to higher prices and fewer vehicles available.

The Role of Technology

Technology plays an important role in enhancing the efficiency of the supply chain. With innovations like automation and data analytics, manufacturers can improve production rates and reduce waste. This helps keep production costs down, ultimately affecting car prices.

Moreover, the integration of technology aids in tracking shipments, ensuring that parts arrive on time. As advancements continue, we can expect even more streamlined processes in the auto industry supply chain.

Ultimately, understanding the supply chain helps consumers make informed decisions. By recognizing how various factors contribute to the final price of a car, buyers can better navigate purchasing decisions and timing.

How disruptions affect car manufacturing

Disruptions in the supply chain can significantly impact car manufacturing. These interruptions can arise from various factors, such as natural disasters, pandemics, or economic shifts. Understanding these effects is essential for both manufacturers and consumers.

Types of Disruptions

There are several types of disruptions that can occur:

- Raw Material Shortages: A lack of essential materials can halt production lines.

- Transportation Issues: Delays in shipping can lead to component shortages.

- Labor Strikes: Disputes can slow or stop manufacturing processes.

- Technological Failures: Equipment breakdowns can lead to lost production time.

When one of these disruptions happens, it causes a ripple effect throughout the manufacturing process. For instance, when there is a shortage of semiconductors, it can delay the production of many modern vehicles that rely on this technology. Customers may notice that their favorite car models become harder to find or see increased prices due to these shortages.

The Impact on Prices

As production slows, the cost of cars tends to rise. Manufacturers may need to adjust pricing strategies to compensate for increased production costs. If fewer cars are available on the market, this can lead to higher demand and, consequently, a spike in prices. So, understanding how these disruptions shape the industry is vital for consumers.

Additionally, manufacturers often look for ways to mitigate these risks. They may diversify their suppliers or invest in technology that enhances efficiency. However, while these strategies can help, they are not foolproof. It’s important for industry stakeholders to stay informed about potential issues in the supply chain.

The role of transportation costs in pricing

The role of transportation costs in pricing is a significant factor in the automotive industry. These costs directly affect how much consumers pay for new cars. When transportation expenses increase, manufacturers often pass those costs on to customers.

Factors Influencing Transportation Costs

Several elements impact transportation costs:

- Fuel Prices: Fluctuations in fuel prices can greatly change logistics costs.

- Logistics Efficiency: More efficient routes can lower transportation costs.

- Distance: Longer distances generally mean higher transportation costs.

- Shipping Methods: Different modes of transport (truck, rail, etc.) carry varying costs.

As these factors change, manufacturers must adjust their strategies, which can lead to differences in car prices. For example, if fuel prices rise, companies may need to raise the retail prices of their vehicles to maintain margins.

Why Transportation Costs Matter

Understanding transportation costs is vital for consumers and manufacturers alike. High transportation costs can lead to limited availability of vehicles in certain areas. This can further influence consumers’ decisions when purchasing cars.

Moreover, manufacturers might opt to keep inventory closer to their markets to reduce shipping times and costs. This decision affects how and where vehicles are sold. Additionally, regional variations in transportation costs can lead to price differences for the same vehicle across different areas.

In conclusion, the impact of transportation costs extends throughout the entire supply chain, shaping the way cars are priced and distributed. Everyone involved in the car buying process should be aware of how these costs can influence their decisions.

Supply chain management strategies for price stability

Supply chain management strategies play a vital role in achieving price stability in the automotive industry. By effectively managing the flow of goods and materials, manufacturers can minimize disruptions and better control costs.

Key Strategies for Stability

Companies often implement several strategies to ensure price stability:

- Diverse Supplier Networks: By having multiple suppliers for key parts, companies can avoid shortages.

- Inventory Management: Efficient tracking of inventory helps manage stock levels, reducing excess costs.

- Flexible Logistics: Adapting logistics strategies can help in responding quickly to market changes.

- Long-term Contracts: Securing prices for raw materials through long-term agreements can hedge against price increases.

These strategies allow manufacturers to respond effectively to market fluctuations and avoid significant price hikes for consumers. For instance, if a material becomes scarce, having a diverse supplier network can help mitigate risks.

The Importance of Technology

Technology also plays a crucial role in managing the supply chain. Tools like data analytics streamline operations by providing insights into trends and potential disruptions. This allows companies to make informed decisions, enhancing their ability to maintain price stability.

Additionally, automation in manufacturing processes can lead to cost reductions. When costs decrease, manufacturers can offer more competitive car prices to consumers. As a result, they not only safeguard their profits but also strive to attract buyers in a competitive market.

By focusing on effective supply chain management, automotive companies can stabilize prices, ensuring their longevity and success in the market. This stability ultimately benefits consumers, who face fewer fluctuations in vehicle pricing.

Future trends in supply chain and car pricing

Future trends in the supply chain and car pricing reveal how innovation and technology will shape the automotive industry. As new challenges arise, manufacturers must adapt to maintain efficiency and meet consumer demands.

Adoption of Technology

One major trend is the increased use of technology. Companies are leveraging artificial intelligence to optimize supply chain operations. This includes predictive analytics to forecast demand and identify potential disruptions before they impact production.

- Automation: Automated processes will improve efficiency and reduce costs.

- Blockchain: This technology can enhance transparency and traceability in the supply chain.

- IoT Devices: Connected devices help monitor inventory levels in real time.

These advancements ensure that manufacturers can respond more swiftly to changes in the market, ultimately stabilizing car prices.

Sustainability Initiatives

Another important trend is the push for sustainability. As consumers become more environmentally conscious, automakers are focusing on greener practices. This includes using sustainable materials and reducing waste during production. Such initiatives not only enhance a brand’s image but can also affect pricing.

For instance, eco-friendly vehicles often come with premium prices due to the added costs of sustainable materials and manufacturing practices. However, as technology advances and these methods become mainstream, we can expect prices to become more competitive.

As the automotive landscape evolves, regulatory changes may also impact supply chains and pricing strategies. New emissions standards might lead manufacturers to innovate in their vehicle designs, which could either drive up costs or lead to more affordable electric alternatives depending on the market response.

FAQ – Frequently Asked Questions about the Impact of Supply Chain Changes on Car Prices

How do disruptions in the supply chain affect car prices?

Disruptions can lead to material shortages and increased manufacturing costs, often resulting in higher car prices.

What role does technology play in managing the supply chain?

Technology, like AI and automation, helps streamline operations, increase efficiency, and reduce costs, which can stabilize prices.

Why are transportation costs important in car pricing?

Transportation costs directly influence how much manufacturers spend to deliver vehicles, which can be passed on to consumers through price increases.

What are some future trends affecting car pricing?

Future trends include sustainability initiatives and advancements in technology that can change manufacturing practices and impact car prices.