Navigating Supply Chain Volatility: Strategies for US Dealers

U.S. auto dealers must proactively implement expert strategies, including supplier diversification and technological integration, to effectively manage and secure inventory amidst persistent supply chain volatility through 2025 and beyond.

The automotive industry in the United States continues to grapple with unprecedented challenges, making navigating supply chain volatility: expert strategies for U.S. dealers to secure inventory through 2025 an essential topic. Dealers are constantly seeking innovative solutions to ensure a steady flow of vehicles and parts to meet consumer demand. This environment demands not just reactive measures, but a forward-thinking approach to resilience and stability.

Understanding the Current Landscape of Supply Chain Volatility

The global automotive supply chain has been a hotbed of disruption over the past few years, a trend that shows little sign of completely abating by 2025. From semiconductor shortages to geopolitical tensions and labor issues, the factors contributing to this instability are multifaceted and deeply interconnected.

Dealers in the U.S. have felt these impacts acutely, facing diminished inventory levels, extended delivery times, and increased operational costs. This section explores the primary drivers of this volatility and their direct consequences for the American automotive market.

Key Drivers of Current Supply Chain Disruptions

Several critical factors continue to fuel the instability within the automotive supply chain. Understanding these drivers is the first step toward developing effective mitigation strategies.

- Semiconductor Shortages: The persistent lack of microchips remains a significant bottleneck, affecting vehicle production across all segments.

- Geopolitical Instability: Conflicts and trade disputes can disrupt shipping routes, increase logistics costs, and limit access to critical raw materials.

- Labor Shortages: Issues across manufacturing, logistics, and port operations contribute to delays and inefficiencies.

- Climate Change Impacts: Extreme weather events can damage infrastructure, disrupt production, and delay shipments.

The confluence of these factors creates a complex environment where traditional supply chain models are no longer sufficient. Dealers must adapt to a new normal characterized by uncertainty and the need for agility.

In conclusion, the current landscape of supply chain volatility is a complex web of interconnected issues. U.S. dealers must grasp these underlying causes to formulate robust strategies for securing inventory and maintaining business continuity in the face of ongoing disruption.

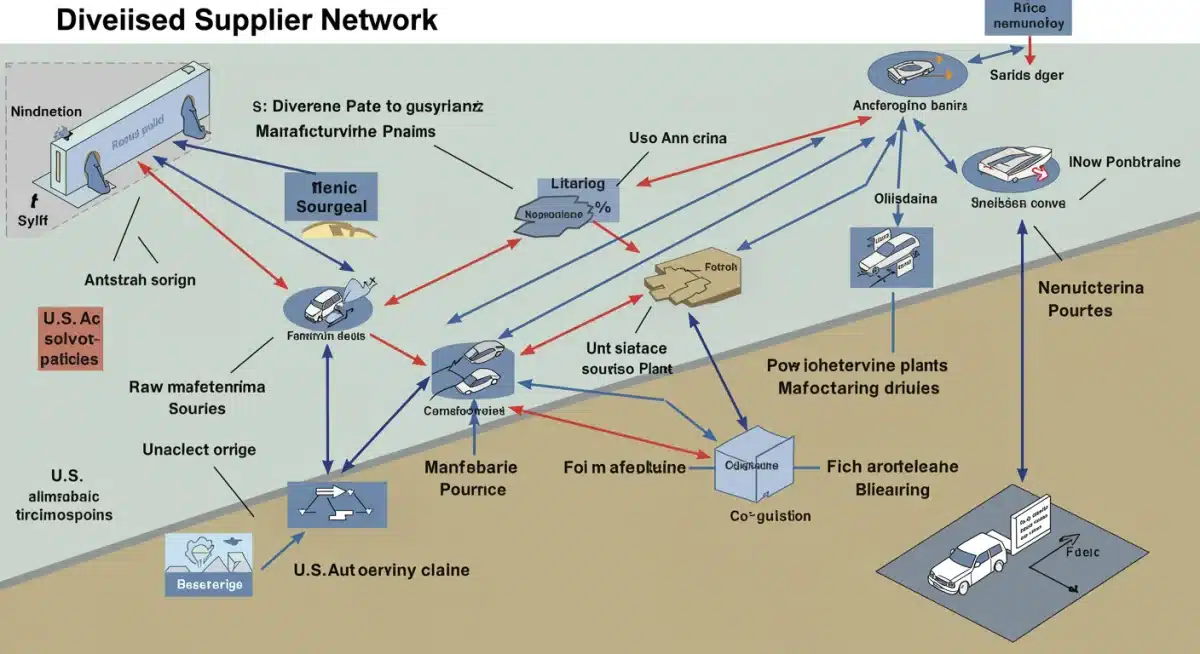

Diversifying Supplier Networks: A Core Strategy

One of the most potent strategies for U.S. dealers to combat supply chain volatility is the diversification of their supplier networks. Over-reliance on a single supplier or a limited geographical region dramatically increases vulnerability to disruptions. By expanding their supplier base, dealers can build a more robust and resilient pipeline for vehicles and parts.

This approach involves not just finding alternative sources but also strategically evaluating new partners based on reliability, quality, and geographical spread. The goal is to create redundancy and flexibility, ensuring that if one supply route is compromised, others can compensate.

Benefits of a Diversified Supplier Base

Expanding the supplier network offers numerous advantages beyond simply mitigating risk. It can lead to improved pricing, access to innovative technologies, and enhanced overall operational efficiency.

- Reduced Risk Exposure: Spreading risk across multiple suppliers minimizes the impact of disruptions from any single source.

- Increased Negotiation Power: A broader network can create competitive pricing opportunities and better terms.

- Access to Innovation: Engaging with diverse suppliers can introduce new technologies and processes.

- Geographical Resilience: Sourcing from different regions reduces susceptibility to localized events like natural disasters or political unrest.

Dealers should consider both domestic and international suppliers, carefully balancing the benefits and risks associated with each. Building strong relationships with these new partners is crucial for long-term success.

Ultimately, a diversified supplier network is not merely a defensive tactic but a strategic investment in future stability and growth. It empowers dealers to maintain inventory levels and respond more effectively to market demands, even in turbulent times.

Leveraging Technology for Enhanced Visibility and Forecasting

In the digital age, technology is an indispensable tool for navigating supply chain volatility: expert strategies for U.S. dealers to secure inventory through 2025. Advanced software solutions, data analytics, and artificial intelligence (AI) can provide unparalleled visibility into the supply chain, enabling more accurate forecasting and proactive decision-making. Dealers who embrace these technologies will be better positioned to anticipate disruptions and optimize their inventory management.

From real-time tracking of shipments to predictive analytics for demand forecasting, technology transforms reactive responses into strategic foresight. This section delves into specific technological applications that can empower U.S. automotive dealers.

Key Technological Solutions for Supply Chain Management

Implementing the right technological tools can revolutionize how dealers manage their inventory and interact with their supply chains.

- Supply Chain Management (SCM) Software: Integrates various processes, from procurement to delivery, offering a holistic view.

- Predictive Analytics and AI: Uses historical data and machine learning to forecast demand, identify potential disruptions, and optimize inventory levels.

- IoT and Real-time Tracking: Internet of Things devices provide live updates on shipment locations and conditions, improving transparency.

- Blockchain Technology: Offers immutable records of transactions and movements, enhancing trust and traceability within the supply chain.

Investing in these technologies requires careful planning and integration but yields significant returns in terms of efficiency, reduced costs, and improved customer satisfaction. The ability to make data-driven decisions is paramount in today’s unpredictable market.

In conclusion, technology acts as an enabler for greater control and understanding within complex supply chains. By adopting advanced digital tools, U.S. dealers can transform their operations, moving from reactive problem-solving to proactive strategic management.

Building Strategic Partnerships and Collaborations

Beyond diversifying suppliers, building strong, strategic partnerships and fostering collaboration within the automotive ecosystem is another critical strategy for U.S. dealers. This involves working closely with manufacturers, logistics providers, and even other dealerships to share information, pool resources, and collectively address supply chain challenges. A collaborative approach creates a stronger, more interconnected network that is better equipped to withstand disruptions.

These partnerships can take many forms, from joint purchasing agreements to shared logistics solutions and information-sharing platforms. The underlying principle is mutual benefit and collective resilience.

Forms of Collaborative Partnerships

Effective partnerships can create synergistic advantages, allowing dealers to overcome hurdles that might be insurmountable individually.

- Manufacturer-Dealer Collaboration: Closer communication and shared forecasting data can optimize production and allocation.

- Logistics Provider Integration: Working with logistics partners to optimize routes, consolidate shipments, and improve delivery reliability.

- Dealer-to-Dealer Networks: Establishing networks for inventory sharing or collective purchasing can enhance flexibility.

- Industry Associations: Leveraging industry groups for shared insights, best practices, and advocacy on supply chain issues.

These collaborations foster a sense of community and shared responsibility, which is invaluable when facing systemic challenges. They allow for a more agile and coordinated response to unforeseen events.

Ultimately, strategic partnerships are about creating a web of support and shared resources that strengthens the entire automotive value chain. For U.S. dealers, this means greater stability and a more reliable path to securing inventory through 2025 and beyond.

Optimizing Inventory Management and Forecasting

Effective inventory management is paramount for navigating supply chain volatility: expert strategies for U.S. dealers to secure inventory through 2025. In an era of unpredictable supply, simply stocking more inventory is not always the answer. Instead, dealers must focus on optimizing their inventory levels, utilizing sophisticated forecasting techniques, and implementing flexible stocking strategies to ensure they have the right vehicles and parts at the right time, without incurring excessive holding costs.

This involves a delicate balance between meeting immediate demand and preparing for future uncertainties. It also requires a deeper understanding of market trends and consumer preferences.

Advanced Inventory Optimization Techniques

Modern inventory management goes beyond simple reorder points. It incorporates data, flexibility, and strategic planning.

- Demand Planning Software: Utilizes advanced algorithms to predict future demand based on historical sales, market trends, and external factors.

- Just-in-Time (JIT) vs. Just-in-Case (JIC): Adapting strategies, sometimes leaning towards JIC for critical components, while maintaining JIT for others.

- Dynamic Safety Stock: Adjusting safety stock levels based on real-time supply chain performance and risk assessments.

- Centralized Inventory Systems: Allowing multiple dealerships within a group to view and share inventory, optimizing overall stock levels.

The goal is to minimize carrying costs while maximizing customer satisfaction through product availability. This requires continuous monitoring and adjustment of inventory strategies based on evolving market conditions and supply chain signals.

In essence, optimizing inventory management is about smart resource allocation. By employing advanced forecasting and flexible stocking methods, U.S. dealers can secure their inventory effectively, even amidst ongoing supply chain fluctuations.

Reshaping Dealership Operations for Resilience

Beyond external supply chain strategies, U.S. dealers must also look inward to reshape their operational structures for greater resilience. This means adopting agile business practices, investing in employee training for adaptability, and creating robust contingency plans. The ability of a dealership to quickly pivot and adapt to changing conditions can significantly mitigate the impact of supply chain disruptions on customer service and profitability.

Operational resilience is about building an organization that can absorb shocks and continue to function effectively, minimizing downtime and maintaining customer trust. This section explores how dealers can foster this internal strength.

Key Operational Adjustments for Enhanced Resilience

Implementing internal changes can create a more robust and responsive dealership environment.

- Cross-Training Employees: Ensuring staff can perform multiple roles to cover absences or shifts in operational focus.

- Digital Transformation: Streamlining internal processes through digitization, reducing reliance on manual tasks and paper-based systems.

- Contingency Planning: Developing clear protocols for various disruption scenarios, from IT outages to unexpected inventory shortages.

- Strong Cash Flow Management: Maintaining healthy financial reserves to weather periods of reduced inventory or increased operational costs.

These internal adjustments complement external supply chain strategies, creating a comprehensive approach to resilience. A well-prepared dealership is better equipped to manage the ebb and flow of inventory and customer demand.

In conclusion, reshaping dealership operations for resilience is about cultivating an adaptive and prepared organization. By focusing on internal agility and robust planning, U.S. dealers can strengthen their ability to overcome supply chain challenges and thrive through 2025.

| Key Strategy | Brief Description |

|---|---|

| Supplier Diversification | Expand network to multiple sources to reduce reliance and minimize disruption risk. |

| Technology Integration | Utilize AI, data analytics, and SCM software for enhanced visibility and forecasting. |

| Strategic Partnerships | Collaborate with manufacturers, logistics, and other dealers for collective resilience. |

| Inventory Optimization | Implement advanced forecasting and flexible stocking strategies for efficient inventory. |

Frequently asked questions about supply chain volatility

The main causes include persistent semiconductor shortages, geopolitical conflicts, labor shortages across various sectors, and disruptions from climate change. These factors collectively create an unpredictable environment for inventory management and vehicle production.

Dealers can diversify by identifying new domestic and international suppliers, evaluating them for reliability and quality, and building strong relationships. This strategy minimizes reliance on single sources and enhances overall supply chain resilience.

Technology, such as SCM software, AI-driven analytics, and IoT tracking, provides enhanced visibility and predictive capabilities. It allows dealers to forecast demand more accurately, track shipments in real-time, and make proactive decisions to avoid disruptions.

Strategic partnerships with manufacturers, logistics providers, and other dealers foster collaboration and shared resources. This collective approach strengthens the entire supply chain, enabling more coordinated responses to challenges and better inventory access.

While some improvements are anticipated, continued volatility is expected through 2025. Dealers must maintain proactive strategies, including diversification, technological adoption, and strong partnerships, to navigate ongoing disruptions effectively and secure inventory.

Conclusion

The journey of navigating supply chain volatility: expert strategies for U.S. dealers to secure inventory through 2025 is not a sprint, but a marathon requiring sustained effort and strategic foresight. By embracing diversification, leveraging cutting-edge technology, forging strong partnerships, optimizing inventory management, and building internal operational resilience, U.S. automotive dealers can transform challenges into opportunities. The future of the automotive market demands agility, innovation, and collaboration, ensuring that despite external pressures, dealerships remain robust and responsive to the needs of their customers.