AI in Auto Supply Chains: 2026 Predictive Analytics to Cut Delays

Artificial intelligence and predictive analytics are projected to reduce automotive supply chain delays by 25% by 2026, creating more resilient and efficient operational frameworks across the industry.

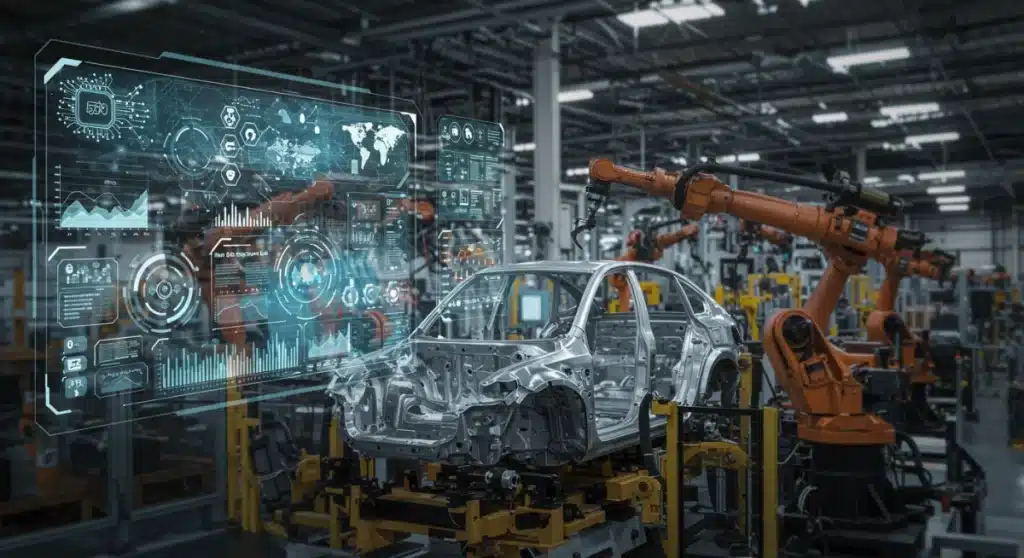

Imagine an automotive industry where parts arrive precisely when needed, production lines rarely halt due to shortages, and vehicle deliveries meet every deadline. This isn’t a distant dream but a rapidly approaching reality. The 2026 Impact of AI on Supply Chains: How Predictive Analytics Will Reduce Delays by 25% in the Auto Sector is set to redefine efficiency, resilience, and responsiveness. This transformation promises not just operational improvements but a fundamental shift in how cars are made and delivered.

the dawn of AI in automotive logistics

The automotive supply chain has historically been a complex web, vulnerable to disruptions ranging from natural disasters to geopolitical shifts. Traditional forecasting methods, while robust, often struggle to keep pace with the sheer volume and velocity of modern data. This is where artificial intelligence steps in, offering a paradigm shift in how we understand and manage these intricate networks.

By leveraging vast datasets, AI algorithms can identify patterns and predict potential bottlenecks long before they materialize. This proactive approach is a game-changer, moving us from reactive problem-solving to predictive prevention. The ability to foresee issues, whether it’s a delay in raw material shipment or a sudden surge in demand for a specific component, allows manufacturers to adapt swiftly, minimizing costly disruptions.

understanding predictive analytics

- Data Ingestion: AI systems process enormous amounts of data from various sources, including sensor data, historical sales, weather forecasts, and global economic indicators.

- Pattern Recognition: Advanced algorithms identify subtle and complex relationships within this data, revealing trends and potential anomalies that human analysis might miss.

- Forecasting Accuracy: Predictive models generate highly accurate forecasts for demand, lead times, and potential risks, significantly improving planning.

The integration of AI into automotive logistics isn’t merely about automation; it’s about intelligent automation. It allows for a deeper, more nuanced understanding of the forces at play within the supply chain, enabling decisions that are not just faster but also fundamentally better. This foundational shift is what will drive the estimated 25% reduction in delays by 2026.

real-time visibility and decision-making

One of the most profound benefits of AI in the supply chain is the creation of unparalleled real-time visibility. Gone are the days of relying on static reports or delayed updates. AI-powered dashboards and systems provide an immediate, comprehensive overview of every moving part, from the factory floor to the dealership.

This constant stream of information, processed and analyzed by AI, empowers decision-makers with actionable insights. If a shipment is rerouted due to unforeseen circumstances, the system immediately updates estimated arrival times and suggests alternative logistics paths. This agility is crucial in an industry where every minute of delay can translate into significant financial losses and customer dissatisfaction.

how AI enhances transparency

- IoT Integration: Internet of Things (IoT) sensors on vehicles, containers, and even individual components feed constant data into the AI system.

- Digital Twins: Virtual replicas of the physical supply chain allow for simulation and testing of various scenarios without real-world risk.

- Automated Alerts: AI systems automatically flag potential issues, sending alerts to relevant personnel and even initiating automated corrective actions.

The ability to make informed decisions rapidly, based on the most current and accurate data, is a cornerstone of a resilient supply chain. This real-time capability ensures that problems are addressed not just quickly, but intelligently, minimizing their ripple effect across the entire automotive production ecosystem.

optimizing inventory and production schedules

Maintaining optimal inventory levels is a perpetual challenge for automotive manufacturers. Too much inventory ties up capital and incurs storage costs, while too little risks production stoppages and missed sales opportunities. AI, particularly through predictive analytics, offers a sophisticated solution to this delicate balancing act.

By analyzing historical demand, market trends, seasonal variations, and even social media sentiment, AI can predict future demand with remarkable precision. This allows companies to fine-tune their inventory, ensuring that components are available just as they are needed, embodying the “just-in-time” principle with unprecedented accuracy. This optimization extends to production schedules, which can be dynamically adjusted based on real-time data and predictive forecasts.

intelligent inventory management

- Demand Forecasting: AI models predict future demand for vehicles and parts, reducing overstocking and stockouts.

- Dynamic Production Planning: Production schedules adapt to real-time supply and demand fluctuations, maximizing efficiency.

- Warehouse Optimization: AI guides the placement and retrieval of parts within warehouses, reducing operational time and costs.

The result is a lean, agile supply chain that responds effectively to market dynamics, minimizing waste and maximizing throughput. This strategic use of AI in inventory and production is a significant contributor to the projected reduction in delays, as it tackles one of the root causes of inefficiency.

enhancing supplier relationship management

The automotive supply chain is only as strong as its weakest link, and often, those links are external suppliers. Managing relationships with hundreds, sometimes thousands, of suppliers globally is a monumental task. AI offers tools to streamline this process, fostering stronger, more transparent, and more efficient partnerships.

Predictive analytics can assess supplier performance, identify potential risks such as financial instability or production capacity limitations, and even suggest alternative suppliers before an issue escalates. This proactive risk management is invaluable, ensuring a continuous flow of materials and components crucial for uninterrupted production.

AI’s role in supplier ecosystems

- Performance Monitoring: AI tracks supplier delivery times, quality metrics, and compliance, providing an objective performance overview.

- Risk Assessment: Predictive models evaluate geopolitical, economic, and operational risks associated with each supplier.

- Automated Communication: AI-powered platforms can automate routine communications, freeing up human resources for more complex negotiations and problem-solving.

By providing insights into supplier reliability and potential vulnerabilities, AI strengthens the entire supply chain network. This collaborative approach, underpinned by data-driven intelligence, ensures that all partners are aligned towards the common goal of efficiency and reliability, directly contributing to delay reduction.

mitigating risks and improving resilience

The automotive industry has learned hard lessons from recent global events, highlighting the critical need for supply chain resilience. AI is at the forefront of building this resilience, transforming how companies anticipate, respond to, and recover from disruptions.

Predictive analytics can simulate various disaster scenarios, from port closures to raw material shortages, allowing companies to develop robust contingency plans. Furthermore, AI systems can continuously monitor global events, providing early warnings of potential disruptions and enabling quick adjustments to logistics and sourcing strategies. This proactive risk mitigation is essential for maintaining operational continuity.

building a resilient supply chain with AI

The ability to model and predict the impact of unforeseen events is a powerful advantage. AI can simulate the effects of a natural disaster on a specific region, calculating its potential impact on lead times and component availability. This allows manufacturers to pre-emptively reroute shipments, diversify sourcing, or adjust production schedules, minimizing the disruption’s impact.

Beyond prediction, AI also plays a crucial role in recovery. In the aftermath of a disruption, AI can quickly assess damage, identify available resources, and optimize recovery efforts, ensuring the quickest possible return to normal operations. This comprehensive approach to risk management is fundamental to achieving and sustaining the targeted 25% reduction in delays.

the road ahead: challenges and future prospects

While the promise of AI in automotive supply chains is immense, the journey isn’t without its challenges. Implementing these sophisticated systems requires significant investment in technology, infrastructure, and skilled personnel. Data privacy and security also remain paramount concerns, requiring robust solutions to protect sensitive supply chain information.

However, the benefits far outweigh these hurdles. The continuous evolution of AI, coupled with advancements in machine learning and big data analytics, will unlock even greater efficiencies. We can anticipate more autonomous decision-making systems, hyper-personalized supply chains, and even more profound reductions in lead times and operational costs. The automotive sector is on the cusp of a logistical revolution.

navigating the future of supply chain AI

- Skill Development: Investing in training programs for employees to manage and leverage AI systems effectively.

- Ethical AI: Developing and deploying AI solutions responsibly, with transparency and accountability.

- Interoperability: Ensuring seamless integration of AI systems across various platforms and with different partners in the supply chain.

The future of automotive supply chains is undeniably intertwined with AI. As the technology matures and its adoption becomes more widespread, the vision of a truly optimized, resilient, and delay-free supply chain will become a reality. The 25% reduction in delays by 2026 is just the beginning of this transformative journey.

| Key Aspect | Impact by 2026 |

|---|---|

| Delay Reduction Target | 25% reduction in automotive supply chain delays. |

| Core Technology | Artificial Intelligence and Predictive Analytics. |

| Key Benefit | Enhanced real-time visibility, optimized inventory, improved resilience. |

| Strategic Advantage | Proactive risk mitigation and dynamic decision-making. |

frequently asked questions about AI in auto supply chains

AI reduces delays by using predictive analytics to forecast demand, identify potential bottlenecks, and optimize logistics in real-time. It analyzes vast datasets to anticipate issues like material shortages or shipping delays, allowing for proactive adjustments before they impact production.

AI leverages diverse data sources including historical sales figures, sensor data from IoT devices, global economic indicators, weather patterns, supplier performance metrics, and even social media trends to build comprehensive predictive models.

While AI will automate routine tasks, it is more likely to augment human capabilities rather than replace them entirely. It will shift roles towards oversight, strategic decision-making, and managing the AI systems, requiring new skill sets and fostering collaboration between humans and AI.

Key challenges include significant initial investment in technology and infrastructure, ensuring data quality and security, integrating AI systems with legacy infrastructure, and overcoming resistance to change within organizations. Skill development for new AI-driven roles is also crucial.

AI enhances supplier relationships by providing objective performance monitoring, early risk assessment, and transparent communication. It helps identify reliable partners, mitigate potential disruptions proactively, and fosters data-driven collaboration for mutual benefit and efficiency.

conclusion

The automotive industry stands at the precipice of a transformative era, with artificial intelligence and predictive analytics acting as the primary catalysts. The ambition to reduce supply chain delays by 25% by 2026 is not merely an optimistic target but a tangible outcome driven by the intelligent application of cutting-edge technology. From real-time visibility and optimized inventory to enhanced supplier management and robust risk mitigation, AI is fundamentally reshaping how vehicles are brought to market. This evolution promises not only greater efficiency and cost savings but also a more resilient and responsive industry, better equipped to navigate the complexities of a globalized world.