Chip Shortage Easing: Projected Effects on US Auto Production

The easing of the chip shortage is projected to significantly boost US auto production in the next 6 months, leading to increased vehicle availability, reduced prices, and a potential reshaping of the automotive market landscape.

The global chip shortage has severely impacted the US auto industry, leading to production cuts and higher prices. As the shortage eases, what are the projected effects of the chip shortage easing on US auto production in the next 6 months?

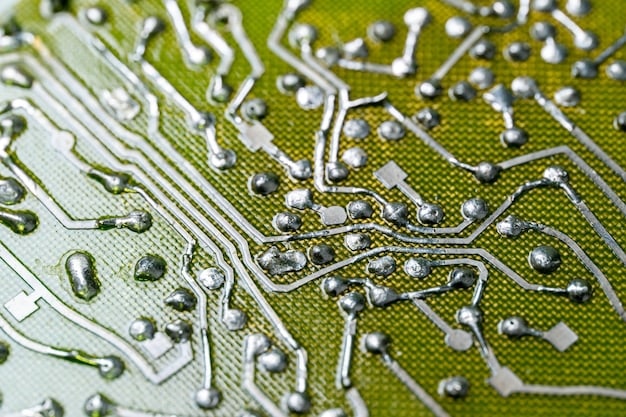

Understanding the Chip Shortage and Its Impact

The chip shortage, a global crisis that began in 2020, has had a profound effect on various industries, with the automotive sector being one of the most severely impacted. Understanding the root causes and the extent of the damage is crucial to appreciate the potential effects of its easing.

The Origins of the Chip Shortage

The chip shortage was primarily triggered by a confluence of factors. The COVID-19 pandemic led to a surge in demand for consumer electronics, such as laptops and gaming consoles, as people shifted to remote work and entertainment. This increased demand strained the capacity of chip manufacturers.

Impact on US Auto Production

The automotive industry relies heavily on semiconductors for various functions, including engine control, infotainment, and safety systems. The chip shortage forced many US automakers to significantly reduce production. This led to reduced vehicle availability, increased prices, and decreased sales.

- Production Cuts: Automakers had to temporarily shut down factories or reduce operating hours due to the lack of chips.

- Price Increases: With fewer new cars available, dealerships increased prices.

- Reduced Sales: The shortage caused a decline in overall vehicle sales in the US market.

The chip shortage exposed the vulnerability of the automotive supply chain. As the situation improves, the industry can anticipate a gradual return to normalcy.

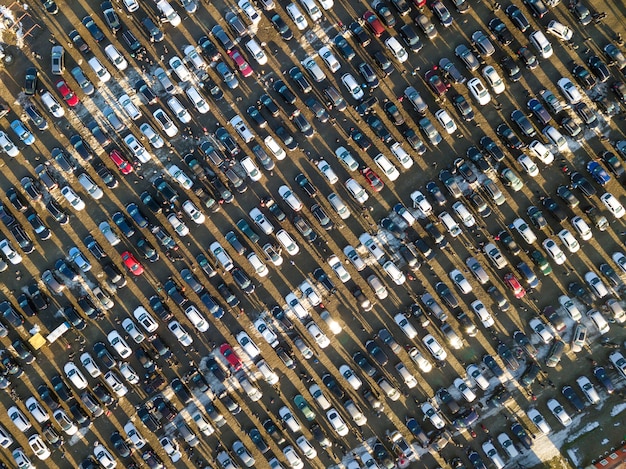

Projected Increase in Vehicle Production

As the chip shortage gradually eases, one of the most significant effects will be a projected increase in vehicle production. Automakers will be able to ramp up production lines and manufacture more vehicles to meet the pent-up demand. This growth is crucial for the health of the automotive sector and the overall economy.

Resuming Full-Scale Operations

With a more stable supply of chips, automakers can resume full-scale operations at their factories. This means recalling workers, increasing production shifts, and maximizing the utilization of manufacturing facilities. The return to full capacity is expected to take several months.

Meeting Pent-Up Demand

During the chip shortage, many consumers postponed their plans to purchase new vehicles due to limited availability and high prices. As production increases, automakers can start meeting the pent-up demand and reducing the backlog of orders.

The increase in vehicle production is a positive sign for the auto industry, signaling a shift from survival mode to recovery and growth. As the industry builds momentum, it is likely to alleviate cost pressures for consumers and bolster the economy.

Effects on New Car Inventory and Availability

The chip shortage has caused a severe shortage of new car inventory at dealerships across the US. With production lines running at reduced capacity, the supply of new vehicles has not been able to keep up with demand. The easing of the chip shortage is expected to gradually improve the availability of new cars.

Replenishing Dealership Inventories

As automakers increase production, they will prioritize replenishing the inventories of dealerships. This means shipping more vehicles to dealerships so they can have a wider selection of models and trim levels available for customers.

- Improved Customer Choice: With more vehicles available, customers will have more choices when selecting a new car.

- Shorter Wait Times: The easing of the shortage should lead to shorter wait times for customers who order custom vehicles.

- Increased Sales: Higher inventory levels should translate into increased sales for dealerships.

The improvement in new car inventory will have a ripple effect throughout the automotive market. As the supply of new cars increases, the prices are expected to become more competitive, encouraging consumer spending.

Potential Impact on New and Used Car Prices

The chip shortage has significantly influenced both new and used car prices. With fewer new cars being produced, demand for used cars surged, driving up prices in both segments. As normalcy returns to the automotive supply chain, there is anticipation that car prices will begin to stabilize.

Stabilizing New Car Prices

As the supply of new cars increases, dealerships will likely reduce prices to attract customers. This could lead to incentives and discounts. The stabilization of new car prices will depend on how quickly automakers can ramp up production and meet demand.

Adjustments in Used Car Market

With more new cars available, demand for used cars may decrease slightly, putting downward pressure on prices. This could create opportunities for consumers looking for affordable transportation options.

Increased vehicle production allows automakers to meet demand, reduce upward pressure on costs, and provide more affordable options for customers.

The Role of Government Policies and Incentives

Government policies and incentives can play a crucial role in accelerating the recovery of the auto industry from the chip shortage. Initiatives aimed at boosting domestic chip manufacturing and supporting the automotive sector can help mitigate supply chain disruptions.

Supporting Domestic Chip Production

The US government has been exploring ways to incentivize domestic chip production through legislation such as the CHIPS Act. By encouraging companies to manufacture chips in the United States, the country can reduce its reliance on foreign suppliers.

Incentives for Electric Vehicle Adoption

Government incentives, such as tax credits and rebates, can encourage consumers to purchase electric vehicles (EVs). This can drive demand for EVs and support the growth of the electric vehicle market. As EV sales increase, automakers will need to secure a stable supply of chips to produce these vehicles.

Government support can catalyze the growth of the domestic automotive industry, promoting innovation, job creation, and sustainable transportation options.

Long-Term Strategies for Supply Chain Resilience

To avoid similar disruptions in the future, automakers are exploring long-term strategies to enhance supply chain resilience. These strategies include diversifying suppliers, building strategic partnerships with chip manufacturers, and investing in research and development of alternative technologies.

- Diversifying Suppliers: Automakers are working to diversify their supplier base so they are not overly reliant on a single source for critical components.

- Strategic Partnerships: Building close relationships with chip manufacturers can provide automakers with better access to supply.

- Investing in R&D: By investing in research and development, automakers can explore alternative technologies that reduce their dependence on traditional semiconductors.

Strategies focused on diversification, collaboration, and innovation, ensure a more stable and secure future for the automotive industry.

| Key Point | Brief Description |

|---|---|

| 📈 Production Surge | Automakers are ramping up production to meet pent-up demand. |

| 🚗 Inventory Boost | Dealerships are replenishing inventories, enhancing customer choice. |

| 💲 Price Stability | New and used car prices are expected to stabilize. |

| 🌱 Supply Resilience | Long-term strategies ensure stable auto production. |

Frequently Asked Questions

▼

Returning to pre-shortage levels will take several months. Automakers must ramp up lines and manage supply chains effectively to recover fully.

▼

Prices should stabilize but might not drop significantly immediately. Factors like inventory levels and demand influence price adjustments.

▼

Policies such as the CHIPS Act, aimed at boosting US chip production, reduce reliance on foreign suppliers and stabilize the industry.

▼

Yes, EVs also need chips for various systems. Improving supply chains helps maintain their production and availability.

▼

Diversifying suppliers, establishing strategic partnerships, and investing in R&D can enhance long-term supply chain stability.

Conclusion

The easing of the chip shortage brings promising prospects for US auto production in the next six months. As production ramps up, dealerships replenish inventories, and prices stabilize, the automotive industry is poised for a robust recovery, reshaping the market for both manufacturers and consumers.