US Auto Industry: Challenges & Opportunities in EV Transition

US auto manufacturers face significant challenges in the transition to electric vehicle (EV) production, including high initial investment costs, supply chain complexities, and the need for a skilled workforce, but also encounter opportunities such as government incentives, growing consumer demand for EVs, and the potential for innovation in battery technology and manufacturing processes.

The automotive industry is undergoing a massive transformation, and for US auto manufacturers, the key challenges and opportunities for US auto manufacturers in the transition to electric vehicle production are profound, reshaping traditional business models and demanding strategic adaptation.

Understanding the Electric Vehicle Transition for US Automakers

The shift from internal combustion engine (ICE) vehicles to electric vehicles (EVs) represents a paradigm shift for the US auto industry. This transition is not merely about swapping out engines; it involves rethinking entire manufacturing processes, supply chains, and business strategies. US automakers must navigate a complex landscape of technological advancements, market dynamics, and regulatory changes to remain competitive.

The Global EV Market Landscape

The global EV market is rapidly expanding, driven by increasing consumer awareness, government incentives, and technological advancements in battery technology. Countries like China and Europe have already made significant strides in EV adoption, creating both challenges and opportunities for US automakers.

US Policy and Regulatory Environment

The US government plays a crucial role in shaping the EV transition through policies such as tax credits, emissions standards, and infrastructure investments. Understanding and adapting to these policies is essential for US automakers to capitalize on opportunities and mitigate potential risks.

- Government incentives and tax credits for EV purchases.

- Increasingly stringent emissions standards.

- Investments in EV charging infrastructure.

The transition to electric vehicles presents both significant challenges and transformative opportunities for US auto manufacturers. By understanding the landscape and adapting quickly, US automakers can secure a leading position in the evolving automotive industry.

Overcoming Manufacturing Challenges in EV Production

One of the primary challenges for US auto manufacturers in the transition to electric vehicle production lies in adapting their existing manufacturing infrastructure. The production of EVs requires different skills, equipment, and processes compared to traditional ICE vehicles. Retooling factories and training the workforce are significant undertakings that demand substantial investment.

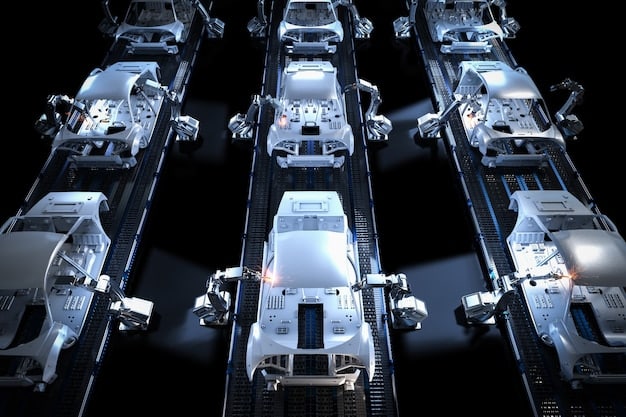

Retooling and Factory Upgrades

Converting existing factories to produce EVs involves significant investments in new equipment and technologies. This includes installing robotic assembly lines, battery manufacturing facilities, and advanced testing equipment.

Supply Chain Management

Securing a reliable supply of critical components such as batteries, semiconductors, and rare earth minerals is essential for EV production. US automakers must diversify their supply chains to mitigate risks associated with geopolitical instability and material shortages.

Successfully navigating these manufacturing challenges will be crucial for US auto manufacturers to ramp up EV production and remain competitive in the global market. Strategic planning, investment, and collaboration will be key to overcoming these hurdles.

Capitalizing on Opportunities in EV Technology

The transition to electric vehicles presents numerous opportunities for innovation and technological advancement. US auto manufacturers can leverage these opportunities to differentiate their EVs and capture a larger share of the market. Investing in research and development is essential to stay ahead of the curve and develop cutting-edge technologies.

Battery Technology Advancements

Battery technology is at the heart of EV innovation. US automakers have the opportunity to develop more efficient, durable, and cost-effective batteries that can extend the range and reduce the price of EVs.

Software and Connectivity

EVs are increasingly becoming software-driven vehicles, with advanced connectivity features and over-the-air updates. US automakers can leverage these technologies to enhance the driving experience, improve vehicle performance, and offer new services to customers.

Electric Powertrain Development

Developing advanced electric powertrains is crucial for improving the performance and efficiency of EVs. US automakers can invest in research and development to create lighter, more powerful, and more efficient electric motors and drive systems.

- Investing in solid-state battery technology.

- Developing advanced driver-assistance systems (ADAS).

- Building strategic partnerships with technology companies.

By capitalizing on these technological opportunities, US auto manufacturers can create innovative and compelling EVs that meet the evolving needs of consumers. Strategic investment in research and development will be critical for long-term success in the EV market.

Meeting Consumer Demand and Preferences for EVs

Understanding and meeting changing consumer demand and preferences are critical for US auto manufacturers in the transition to electric vehicles. As EVs become more mainstream, consumers are increasingly demanding longer ranges, faster charging times, and more affordable prices.

Addressing Range Anxiety

Range anxiety, the fear of running out of battery power, is a major concern for potential EV buyers. US automakers can address this concern by developing EVs with longer ranges and investing in public charging infrastructure.

Improving Charging Infrastructure

The availability of convenient and reliable charging infrastructure is essential for widespread EV adoption. US automakers can collaborate with government and private companies to expand the charging network and improve the charging experience.

Affordable EV Options

The high cost of EVs is a barrier for many consumers. US automakers can address this issue by developing more affordable EV options and offering incentives to make EVs more accessible.

By addressing these factors and developing EVs that meet consumer needs and preferences, US auto manufacturers can drive broader EV adoption and secure a leading position in the market.

Adapting Business Models for the EV Era

The transition to electric vehicles requires US auto manufacturers to adapt their traditional business models. The shift from selling ICE vehicles to selling EVs involves new revenue streams, service models, and customer relationships. Embracing these changes is essential for long-term success in the EV era.

New Revenue Streams

EVs offer opportunities for new revenue streams, such as subscription services for software and connectivity features, over-the-air updates, and energy management services.

Service and Maintenance Models

EVs require less maintenance than ICE vehicles, which can impact traditional service and maintenance revenue. US automakers can develop new service models that focus on software updates, battery maintenance, and advanced diagnostics.

Direct-to-Consumer Sales

Some US automakers are exploring direct-to-consumer sales models to bypass traditional dealerships and offer a more seamless and personalized customer experience.

By adapting their business models and embracing new revenue streams, service models, and customer relationships, US auto manufacturers can thrive in the evolving EV market. Flexibility and innovation will be key to navigating these changes.

Navigating the Workforce Transition

The transition to electric vehicle production necessitates a significant shift in the automotive workforce. US auto manufacturers must invest in retraining existing employees and attracting new talent with expertise in электротехника, software development, and battery technology. A skilled workforce is essential for successful EV production and innovation.

Retraining Existing Employees

Retraining existing employees is crucial to ensure that they have the skills needed to work on EVs. This includes training in battery assembly, electric motor maintenance, and software diagnostics.

Attracting New Talent

Attracting new talent with expertise in электротехника, software development, and battery technology is essential for driving innovation and competitiveness. US automakers can partner with universities and vocational schools to develop training programs and internship opportunities.

Investing in Education and Training

Investing in education and training programs is crucial to develop a skilled workforce for the EV era. US automakers can support educational initiatives and create partnerships with community colleges and technical schools.

By investing in workforce development and attracting and retaining skilled employees, US auto manufacturers can ensure a smooth transition to EV production and maintain a competitive edge in the global market.

| Key Point | Brief Description |

|---|---|

| 🛠️ Manufacturing Adaptation | Upgrading facilities for EV production requires significant investment. |

| 🔋 Battery Technology | Advancements in battery tech can improve EV range and affordability. |

| ⚡ Charging Infrastructure | Expanding charging networks is crucial for EV adoption. |

| 🧑💼 Workforce Transition | Retraining employees for EV-related jobs is essential. |

FAQ

▼

The biggest challenges include the high costs of retooling factories, securing a reliable supply chain, and adapting to new manufacturing processes. Additionally, overcoming consumer concerns like range anxiety and charging availability is crucial.

▼

Opportunities include government incentives, growing consumer demand, and the potential for innovation in battery technology. They can also develop new business models centered around software and connectivity, creating new revenue streams.

▼

US automakers are developing EVs with longer ranges and investing in public charging infrastructure. They are also partnering with charging network providers to improve the charging experience and reduce consumer anxiety.

▼

Government policies, such as tax credits, emissions standards, and infrastructure investments, significantly shape the EV transition. These policies incentivize EV adoption, encourage innovation, and support the development of charging infrastructure.

▼

The EV transition necessitates retraining existing employees and attracting new talent with expertise in электротехника, software development, and battery technology. This requires investment in education and training programs to develop a skilled workforce.

Conclusion

The transition to electric vehicle production presents both formidable challenges and exciting opportunities for US auto manufacturers. By addressing manufacturing hurdles, capitalizing on technological advancements, meeting consumer demand, adapting business models, and navigating the workforce transition, US automakers can secure a competitive position in the evolving automotive landscape.