Chip Shortage Easing: Projected Effects on US Auto Production in 6 Months

The easing of the chip shortage is projected to positively impact US auto production within the next 6 months, potentially leading to increased vehicle availability, reduced prices, and a boost in overall industry output after a period of significant constraint.

The automotive industry has been grappling with a severe chip shortage for the past couple of years, significantly impacting **what are the projected effects of the chip shortage easing on US auto production in the next 6 months?**

Understanding the Chip Shortage and Its Impact

The global chip shortage, primarily affecting semiconductors, has had a profound impact on various industries, with the automotive sector being among the hardest hit. Understanding the root causes and ripple effects of this shortage is crucial to anticipating future trends.

What Caused the Chip Shortage?

Several factors converged to create the perfect storm that led to the chip shortage. These include increased demand for electronics during the pandemic, supply chain disruptions, and geopolitical tensions.

- Increased Demand for Electronics: With more people working and learning from home, the demand for laptops, tablets, and other electronic devices surged, diverting chip supplies away from the automotive industry.

- Supply Chain Disruptions: Lockdowns and other pandemic-related disruptions hampered chip production and transportation, creating bottlenecks in the supply chain.

- Geopolitical Tensions: Trade disputes and political instability in regions with significant chip manufacturing capacity added further complexity to the supply chain.

The chip shortage has been a multifaceted crisis, highlighting the interconnectedness of global supply chains and the vulnerability of industries reliant on specialized components.

Impact on US Auto Production

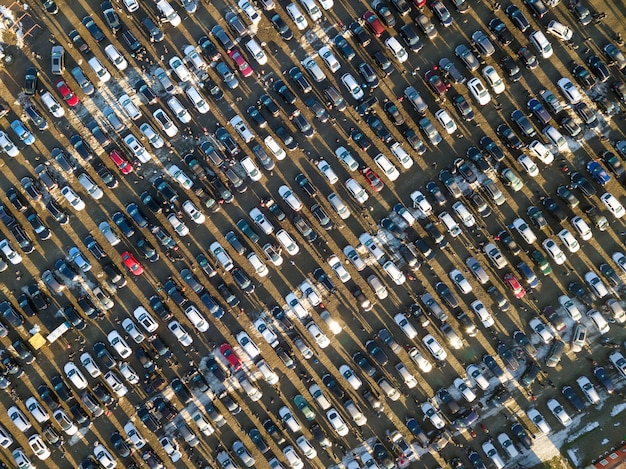

The chip shortage has led to significant production cuts, factory shutdowns, and reduced vehicle inventory across the United States. This has had a ripple effect on dealerships, consumers, and the broader economy.

Automakers have been forced to prioritize production of high-margin vehicles, leading to shortages of more affordable models. This has driven up prices and made it more difficult for consumers to purchase new cars.

The impact of the chip shortage has been acutely felt by auto workers, with temporary layoffs and reduced work hours becoming commonplace. This has created economic hardship for many families and communities dependent on the auto industry.

In summary, the chip shortage has disrupted US auto production, leading to reduced vehicle availability, higher prices, and economic uncertainty.

Signs of Easing Chip Supply Constraints

While the chip shortage is not yet fully resolved, there are emerging signs that supply constraints are beginning to ease. Increased chip production capacity, improved supply chain management, and shifting consumer demand are contributing to this trend.

Increased Chip Production Capacity

Chip manufacturers have been investing heavily in expanding production capacity to meet the growing global demand. New fabrication plants are coming online, and existing facilities are increasing output.

Government incentives and policies aimed at boosting domestic chip production are also playing a role in expanding capacity within the United States. This is expected to reduce reliance on foreign suppliers and enhance supply chain resilience.

The increased production capacity is not only addressing the immediate shortage but also laying the foundation for long-term stability in the chip supply chain.

Improved Supply Chain Management

Automakers and chip suppliers are working more closely together to improve supply chain visibility and coordination. This includes sharing data, optimizing inventory management, and diversifying sourcing strategies.

Advanced technologies like artificial intelligence and machine learning are being used to predict demand, identify potential bottlenecks, and optimize logistics. This is helping to streamline the flow of chips from manufacturers to automakers.

By enhancing supply chain management, companies are becoming more agile and responsive to changing market conditions.

Shifting Consumer Demand

As the initial surge in demand for electronics during the pandemic begins to subside, more chip capacity is becoming available for the automotive industry. Consumer spending is shifting from goods to services, reducing pressure on the chip supply chain.

The easing of demand for certain consumer electronics is freeing up manufacturing capacity that can be redirected to meet the needs of the auto industry.

Overall, the combination of increased production capacity, improved supply chain management, and shifting consumer demand is creating a more favorable environment for US auto production.

Projected Effects on US Auto Production

With chip supply constraints easing, the US auto industry is poised for a rebound in production. This is expected to have several positive effects, including increased vehicle availability, reduced prices, and improved economic outlook.

Increased Vehicle Availability

As chip supplies normalize, automakers will be able to ramp up production and replenish depleted vehicle inventories. This will provide consumers with more choices and reduce waiting times for new cars.

Dealers will have a wider range of models and trim levels available, making it easier for customers to find the vehicles they want. This will also help to alleviate the backlog of orders that has accumulated during the chip shortage.

The increased vehicle availability will benefit both consumers and automakers, contributing to a more robust and competitive market.

Reduced Vehicle Prices

The easing of the chip shortage is expected to put downward pressure on vehicle prices. As supply increases, automakers will have less incentive to charge premium prices for limited inventory.

Increased competition among automakers and dealerships will also contribute to price reductions. Consumers will be able to negotiate better deals and find more affordable options.

While prices may not return to pre-pandemic levels immediately, the trend is expected to be towards greater affordability and value for consumers.

Improved Economic Outlook

A rebound in US auto production will have a positive impact on the broader economy. Increased manufacturing activity will create jobs, stimulate economic growth, and boost consumer confidence.

The auto industry is a significant contributor to the US economy, and its recovery will have a ripple effect on related industries, such as steel, rubber, and electronics. This will help to strengthen the overall economy and improve the financial well-being of American families.

In conclusion, the projected effects of the chip shortage easing on US auto production are overwhelmingly positive, promising increased vehicle availability, reduced prices, and an improved economic outlook.

Potential Challenges and Risks

While the outlook for US auto production is improving, several potential challenges and risks could still derail the recovery. These include lingering supply chain disruptions, geopolitical instability, and changing consumer preferences.

Lingering Supply Chain Disruptions

Despite progress in easing the chip shortage, the global supply chain remains vulnerable to disruptions. Events such as natural disasters, labor strikes, and trade disputes could create new bottlenecks and delay the recovery.

Automakers need to continue diversifying their sourcing strategies and building resilience into their supply chains to mitigate the impact of potential disruptions.

Monitoring the supply chain closely and proactively addressing potential risks is crucial for ensuring a smooth and sustained recovery in auto production.

Geopolitical Instability

Geopolitical tensions and conflicts could disrupt chip production and transportation, particularly in regions with significant manufacturing capacity. This could exacerbate the chip shortage and delay the recovery of US auto production.

Diplomatic efforts to de-escalate tensions and promote stability are essential for maintaining a reliable global supply chain.

Businesses and governments need to work together to address geopolitical risks and safeguard the flow of critical components.

Shifting Consumer Preferences

Changes in consumer preferences, such as a shift towards electric vehicles or a decline in demand for certain types of vehicles, could impact auto production. Automakers need to adapt to these changing preferences and invest in new technologies and models to remain competitive.

Understanding and responding to consumer demand is crucial for ensuring long-term success in the auto industry.

Innovation and flexibility are key to navigating the evolving landscape of consumer preferences and staying ahead of the curve.

Strategies for Automakers to Maximize Recovery

To fully capitalize on the easing of the chip shortage and maximize their recovery, US automakers need to implement strategic initiatives focused on supply chain resilience, technology investment, and customer engagement.

Strengthening Supply Chain Resilience

Diversifying sourcing strategies, building strategic partnerships, and investing in supply chain visibility are essential for enhancing resilience. Automakers should also consider establishing regional manufacturing hubs to reduce reliance on global supply chains.

Implementing robust risk management processes and developing contingency plans are also crucial for mitigating the impact of potential disruptions.

By strengthening supply chain resilience, automakers can minimize the risk of future shortages and ensure a stable flow of components.

Investing in Technology and Innovation

Investing in advanced manufacturing technologies, electric vehicle development, and autonomous driving capabilities is crucial for long-term competitiveness. Automakers should also explore opportunities to integrate new technologies into their supply chains and customer experience.

Embracing innovation and staying ahead of technological trends is essential for capturing new market opportunities and maintaining a competitive edge.

By investing in technology and innovation, automakers can position themselves for success in the evolving automotive landscape.

Enhancing Customer Engagement

Improving customer communication, offering personalized experiences, and building brand loyalty are key to driving sales and maximizing recovery. Automakers should also leverage digital channels to engage with customers and provide seamless online-to-offline experiences.

Understanding customer needs and preferences is essential for developing products and services that resonate with target markets.

By enhancing customer engagement, automakers can build stronger relationships with their customers and drive sustainable growth.

Future Outlook for US Auto Production

The future outlook for US auto production is optimistic, with the easing of the chip shortage paving the way for a sustained recovery. However, vigilance and adaptability are essential for navigating potential challenges and capitalizing on emerging opportunities. The impact of **what are the projected effects of the chip shortage easing on US auto production in the next 6 months?** is poised to be significant.

Continued Recovery and Growth

As chip supplies normalize and supply chains stabilize, US auto production is expected to continue its recovery and return to pre-pandemic levels. This will drive economic growth, create jobs, and improve consumer confidence.

Automakers that proactively address potential challenges and invest in strategic initiatives will be best positioned to capitalize on the recovery and achieve sustainable growth.

The long-term outlook for US auto production is bright, with the industry poised for a new era of innovation and prosperity.

Emerging Trends and Opportunities

The automotive industry is undergoing a period of rapid transformation, with electric vehicles, autonomous driving, and connected car technologies emerging as key trends. Automakers that embrace these trends and invest in new capabilities will be best positioned to succeed in the future.

Sustainability and environmental responsibility are also becoming increasingly important, driving demand for more fuel-efficient and eco-friendly vehicles.

By understanding and adapting to these emerging trends, automakers can unlock new opportunities and create long-term value.

| Key Point | Brief Description |

|---|---|

| 🚗 Production Increase | Auto production is expected to rise as chip supply improves. |

| 💰 Price Relief | Vehicle prices might decrease due to increased supply. |

| 📈 Economic Boost | Overall economy is expected to strengthen with auto sector recovery. |

| 🏭 Job Growth | Increased auto production might lead to more jobs in the sector. |

FAQ

▼

Production rates might start improving in the next few months, but it will take time to reach pre-shortage levels. Expect gradual increases rather than an immediate surge.

▼

While prices are expected to ease, significant drops may not happen immediately due to inflation and other economic factors. Gradual price adjustments are more likely.

▼

Increased chip availability can boost EV production, helping automakers meet growing demand for electric vehicles. This may lead to more EV models and options.

▼

Yes, geopolitical tensions or new pandemics could disrupt supply chains again. Automakers are working on diversifying their sources to minimize future impacts.

▼

As new car production increases, the used car market should stabilize and prices may soften as more consumers opt for new vehicles instead of used ones.

Conclusion

In conclusion, the projected easing of the chip shortage holds promising implications for US auto production, offering a pathway to increased vehicle availability, more reasonable prices, and a general uplift for the industry and economy. While challenges remain, strategic actions and adaptation will determine the extent and sustainability of this recovery.