Automotive Manufacturing: Latest Tech & Efficiency Boosts

Latest innovations in automotive manufacturing technology, such as AI-driven automation, 3D printing, and advanced robotics, are significantly boosting production efficiency by reducing costs, minimizing errors, and accelerating production cycles.

The automotive industry is undergoing a technological revolution. This article delves into what are the latest innovations in automotive manufacturing technology and their impact on production efficiency?, exploring the cutting-edge advancements reshaping how cars are made and their profound effects on cost, speed, and quality.

Artificial intelligence and machine learning

Artificial intelligence (AI) and machine learning (ML) are no longer futuristic concepts but integral components of modern automotive manufacturing. These technologies are optimizing various aspects of the production process, from design to quality control.

By leveraging AI and ML, automotive manufacturers can achieve unprecedented levels of efficiency and precision, leading to significant cost savings and improved product quality.

Predictive Maintenance

Predictive maintenance is one of the most impactful applications of AI in automotive manufacturing. By analyzing data from sensors and equipment, AI algorithms can predict when machines are likely to fail.

Optimized Production Schedules

AI and ML algorithms can analyze vast amounts of data to optimize production schedules, minimizing downtime and maximizing throughput. This dynamic scheduling ensures that resources are allocated efficiently.

- Reduced Downtime: AI-driven predictive maintenance reduces unplanned downtime, keeping production lines running smoothly.

- Improved Resource Allocation: Optimized schedules ensure resources are used efficiently, reducing waste and costs.

- Enhanced Production Throughput: AI algorithms maximize the number of vehicles produced in a given timeframe.

- Data-Driven Decisions: Informed decisions based on real-time data enhance overall production efficiency.

AI and ML enhance predictive maintenance and optimized scheduling, leading to more efficient and reliable automotive manufacturing processes.

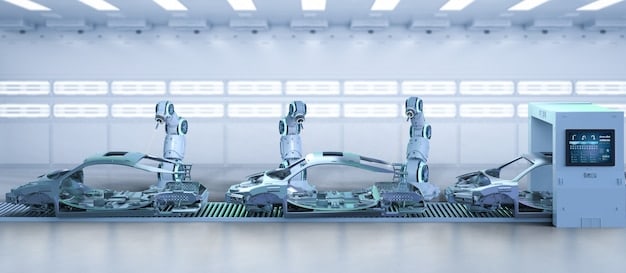

Robotics and automation

Robotics and automation have long been key components of automotive manufacturing, but recent advancements have taken their capabilities to new heights. These technologies are now more flexible, intelligent, and integrated than ever before.

These improvements are driving significant gains in production efficiency, allowing manufacturers to produce vehicles faster and with higher quality.

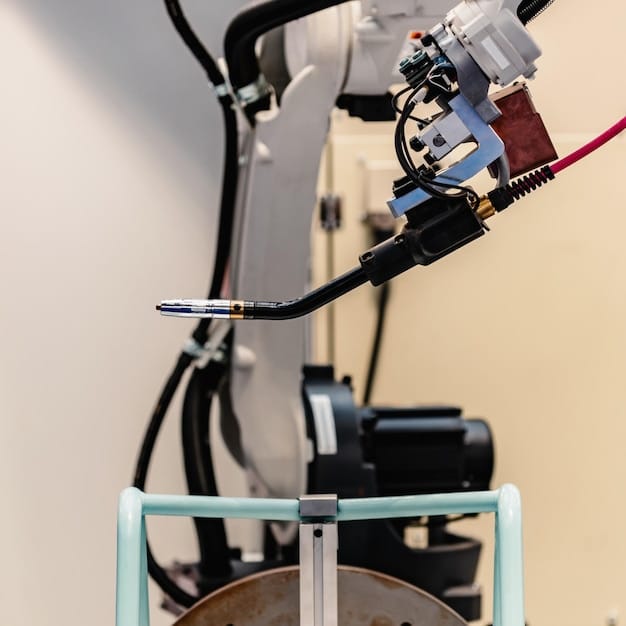

Collaborative Robots (Cobots)

Cobots are designed to work alongside human workers, assisting with tasks that are repetitive, physically demanding, or dangerous. This collaboration enhances both efficiency and worker safety.

Autonomous Guided Vehicles (AGVs)

AGVs are used to transport materials and components throughout the factory floor without human intervention. These vehicles can navigate complex environments and adapt to changing conditions, ensuring a smooth and efficient flow of materials.

- Enhanced Safety: Cobots reduce the risk of workplace injuries by handling dangerous and physically demanding tasks.

- Increased Speed: Automation accelerates the production process, reducing cycle times and increasing throughput.

- Improved Accuracy: Robots perform tasks with greater precision and consistency than humans, reducing defects and waste.

- Cost Savings: Automation reduces labor costs and improves overall efficiency, leading to significant cost savings.

Cobots enhance safety, increase speed, and improve accuracy, while AGVs ensure a seamless material flow, optimizing automotive production lines.

3D printing and additive manufacturing

3D printing, also known as additive manufacturing, has emerged as a game-changing technology in the automotive industry. It enables the creation of complex parts and prototypes with unprecedented speed and flexibility.

With this technology, automotive manufacturers can reduce lead times, lower costs, and create innovative designs that were previously impossible to produce using traditional methods.

Rapid Prototyping

3D printing allows manufacturers to quickly create prototypes of new parts and designs, enabling faster iteration and testing. This accelerates the design process and reduces time-to-market for new vehicles.

Customized Parts

3D printing makes it possible to create customized parts for niche vehicles or aftermarket applications. This opens up new opportunities for personalization and allows manufacturers to cater to specific customer needs.

3D printing enables rapid prototyping and customized parts production, which accelerates design iterations and caters to specific customer needs.

Virtual reality and augmented reality

Virtual reality (VR) and augmented reality (AR) technologies are transforming various aspects of automotive manufacturing, from design and training to maintenance and quality control.

By leveraging VR and AR, manufacturers can improve efficiency, reduce errors, and enhance collaboration across different teams and departments.

Design and Simulation

VR allows designers and engineers to immerse themselves in virtual prototypes of vehicles and components, enabling them to identify and resolve design flaws early in the process. This reduces the need for physical prototypes and saves time and money.

Training and Education

AR can be used to overlay digital information onto real-world equipment, providing workers with step-by-step instructions and guidance. This reduces errors and improves overall efficiency.

- Reduced Errors: VR and AR technologies minimize design flaws and human errors, improving product quality.

- Enhanced Collaboration: These technologies facilitate better communication and collaboration between different teams and departments.

- Improved Training: VR and AR provide workers with immersive and effective training experiences, enhancing their skills and knowledge.

VR and AR enhance design accuracy, facilitate collaboration, train employees, and improve overall efficiency in automotive manufacturing.

Big data analytics and iot

Big data analytics and the Internet of Things (IoT) are providing automotive manufacturers with unprecedented insights into their operations. By collecting and analyzing data from various sources, manufacturers can identify bottlenecks, optimize processes, and improve overall efficiency.

These technologies enable real-time decision-making and continuous improvement, driving significant gains in productivity and profitability.

Real-Time Monitoring

IoT sensors collect data from machines, equipment, and processes throughout the factory floor. This data is then analyzed in real-time to identify anomalies, predict failures, and optimize performance.

Supply Chain Optimization

Big data analytics can be used to optimize the supply chain, ensuring that materials and components are delivered on time and at the lowest possible cost. This reduces lead times and improves overall efficiency.

- Improved Decision-Making: Data-driven insights enable informed decisions, leading to better outcomes and improved efficiency.

- Reduced Costs: Optimized processes and supply chains reduce waste and lower costs, driving significant savings.

- Increased Agility: Real-time monitoring and analytics allow manufacturers to respond quickly to changing conditions, improving agility and competitiveness.

Big data and IoT drive informed decisions, optimize supply chains, and improve overall efficiency for automotive manufacturers.

Sustainability and green manufacturing

Sustainability has become a major focus in the automotive industry, with manufacturers increasingly looking for ways to reduce their environmental impact and promote green manufacturing practices.

This not only helps to protect the planet but also improves efficiency, reduces costs, and enhances brand reputation.

Energy Efficiency

Manufacturers are investing in energy-efficient equipment and processes to reduce their carbon footprint and lower energy costs. This includes using LED lighting, optimizing HVAC systems, and implementing energy management systems.

Waste Reduction

Manufacturers are implementing waste reduction programs to minimize the amount of materials that end up in landfills. This includes recycling materials, reducing packaging, and implementing closed-loop manufacturing processes.

- Reduced Environmental Impact: Sustainable practices minimize the environmental footprint of automotive manufacturing, protecting the planet.

- Lower Costs: Energy efficiency and waste reduction programs lower operating costs, driving significant savings.

- Enhanced Brand Reputation: Consumers are increasingly demanding sustainable products and practices, enhancing brand reputation and loyalty.

Sustainability brings numerous benefits, including reduced environmental impact, lower costs, and enhanced brand reputation. Green manufacturing practices not only contribute to a healthier planet but also drive operational efficiency and competitiveness.

| Key Point | Brief Description |

|---|---|

| 🤖 AI-Driven Automation | Enhances precision, minimizes errors in production. |

| ⚙️ Advanced Robotics | Increases speed and consistency in assembly processes. |

| 🖨️ 3D Printing | Enables rapid prototyping and customized parts production. |

| ⚡️ Sustainable Practices | Reduces waste and energy, improving brand value. |

Frequently Asked Questions

▼

AI enhances predictive maintenance, optimizes production schedules, and improves data-driven decision-making, leading to significant efficiency gains and cost savings in automotive manufacturing.

▼

Collaborative robots, or cobots, improve production lines by working alongside human workers, assisting with repetitive or dangerous tasks, thus enhancing safety and increasing overall efficiency.

▼

3D printing enables rapid prototyping of new parts and the creation of customized components, reducing lead times, lowering costs, and facilitating innovative designs that were previously impossible.

▼

VR and AR improve design accuracy by allowing engineers to identify flaws early, enhance team collaboration, provide effective training, and minimize human errors, leading to higher product quality.

▼

Sustainable practices reduce environmental impact, lower operating costs through energy efficiency and waste reduction, and enhance brand reputation, aligning with consumer demand for eco-friendly products.

Conclusion

The automotive manufacturing industry is being revolutionized by a wave of technological innovations. From AI-driven automation to advanced robotics, 3D printing, VR/AR, and sustainable practices, these advancements are significantly boosting production efficiency, reducing costs, and improving product quality. As these technologies continue to evolve, automotive manufacturers must embrace them to stay competitive and meet the demands of a rapidly changing market.