Automotive Manufacturing: Tech Innovations & Production Efficiency

Latest innovations in automotive manufacturing technology, such as AI-driven automation and advanced materials, are revolutionizing production efficiency by reducing waste, enhancing precision, and accelerating manufacturing cycles.

The automotive industry is undergoing a dramatic transformation, driven by technological advancements. What are the Latest Innovations in Automotive Manufacturing Technology and Their Impact on Production Efficiency? From AI-powered robots to 3D printing, discover how these technologies are reshaping car production.

The Dawn of Smart Manufacturing in Automotive

Smart manufacturing is no longer a futuristic concept, but a present-day reality in the automotive industry. These technologies enable data-driven decision-making, predictive maintenance, and real-time optimization of production processes.

AI-Driven Automation

Artificial intelligence (AI) is revolutionizing automation in automotive manufacturing. AI algorithms can analyze vast amounts of data from sensors and machines to optimize production flows, predict equipment failures, and improve quality control.

Predictive Maintenance

One of the biggest impacts of AI in manufacturing is predictive maintenance. By analyzing data from sensors on machines, AI algorithms can predict when a machine is likely to fail. This allows manufacturers to schedule maintenance proactively, minimizing downtime and maximizing production efficiency.

- Reduced Downtime: AI helps predict and prevent equipment failures.

- Optimized workflows: Dynamic adjustment of processes for peak performance.

- Enhanced quality control: Real-time detection of defects reduces waste.

The integration of smart manufacturing technologies is reshaping automotive production, leading to greater efficiency and responsiveness to market demands. By harnessing the power of data and automation, manufacturers can optimize their operations and stay competitive in a rapidly evolving industry.

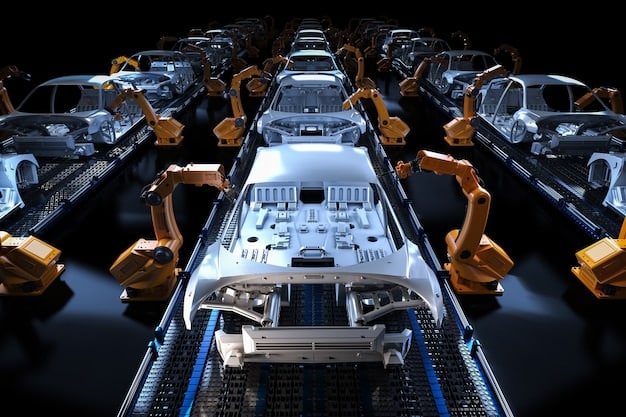

Advanced Robotics and Automation Systems

Robotics in automotive manufacturing has evolved beyond simple assembly line tasks. Modern robots are equipped with advanced sensors, AI, and machine learning capabilities, enabling them to perform complex tasks with greater precision and speed.

Collaborative Robots (Cobots)

Cobots are designed to work alongside human workers safely, assisting with tasks such as lifting heavy parts, performing repetitive motions, and ensuring consistent quality. They are equipped with sensors that detect human presence and automatically stop if a collision is imminent.

Autonomous Guided Vehicles (AGVs)

AGVs are used to transport materials and parts throughout the factory floor, optimizing logistics and reducing the need for manual handling. They can be programmed to follow specific routes, avoid obstacles, and deliver materials to the right location at the right time.

- Enhanced precision: Robotic systems minimize errors in assembly.

- Increased speed: Automation significantly accelerates production cycles.

- Improved safety: Cobots reduce risks to human workers.

Advanced robotics and automation systems are critical components of the modern automotive factory. By integrating these technologies, manufacturers can increase efficiency, improve quality, and create a safer working environment.

Additive Manufacturing (3D Printing)

Additive manufacturing, commonly known as 3D printing, is transforming automotive manufacturing by enabling the creation of customized parts, rapid prototyping, and on-demand production.

Rapid Prototyping

3D printing allows automotive designers and engineers to quickly create prototypes of new parts and components. This accelerates the design process, allowing for faster iteration and refinement of new products.

Customized Parts

One of the significant advantages of 3D printing is the ability to create customized parts for specific vehicles or customers. This is particularly useful for luxury and high-performance vehicles, where customization is a key selling point.

Additive manufacturing is revolutionizing the automotive industry by enabling rapid prototyping, customized parts, and on-demand production. As the technology continues to evolve, it is likely to play an even greater role in shaping the future of car manufacturing.

The Role of Big Data and Analytics

Big data and analytics are transforming the automotive industry by providing manufacturers with valuable insights into their production processes, customer preferences, and market trends. By analyzing vast amounts of data, manufacturers can optimize their operations, improve product quality, and enhance customer satisfaction.

- Predictive maintenance: Data analysis prevents equipment failures.

- Optimized inventory: Efficient management of parts and materials.

- Enhanced design: Customer data refines product development.

Sustainable Manufacturing Practices

Sustainability is becoming an increasingly important consideration for automotive manufacturers. As consumers become more environmentally conscious, manufacturers are adopting sustainable practices to reduce their carbon footprint, minimize waste, and conserve resources.

Eco-Friendly Materials

Automotive manufacturers are increasingly using eco-friendly materials in their vehicles, such as recycled plastics, bio-based composites, and lightweight alloys. These materials reduce the environmental impact of vehicle production and improve fuel efficiency.

By adopting sustainable manufacturing practices, automotive manufacturers can reduce their environmental impact, conserve resources, and meet the growing demand for eco-friendly vehicles.

The Impact of Digital Twins

Digital twins are virtual replicas of physical assets, processes, or systems. In automotive manufacturing, digital twins are used to simulate and optimize production processes, predict equipment failures, and train workers.

Simulating Production Processes

Digital twins can be used to simulate the entire automotive manufacturing process, from design and engineering to assembly and testing. This allows manufacturers to identify potential bottlenecks, optimize workflows, and improve overall efficiency.

Digital twins are transforming automotive manufacturing by enabling simulation, optimization, and training. As the technology continues to evolve, it is likely to play an even greater role in shaping the future of car production.

| Key Innovation | Brief Description |

|---|---|

| 🤖 AI Automation | Uses AI to optimize production and predict equipment failures. |

| ⚙️ Advanced Robotics | Employs cobots and AGVs for precise and safe manufacturing. |

| 🖨️ 3D Printing | Enables rapid prototyping and creation of customized parts. |

| 🍃 Sustainable Practices | Focuses on eco-friendly materials and waste reduction methods. |

Frequently Asked Questions

▼

AI primarily optimizes production by analyzing vast data sets to predict equipment failures and enhance quality control, thus minimizing downtime and improving overall efficiency.

▼

Cobots enhance safety by working alongside human workers, handling heavy or repetitive tasks. They are equipped with sensors that halt operation upon detecting human presence, preventing collisions.

▼

3D printing facilitates rapid prototyping, allowing quick design iterations and testing. It also enables the production of customized parts tailored to specific vehicle models or customer needs.

▼

Sustainability addresses growing consumer demand for eco-friendly products, reduces the carbon footprint, minimizes waste, and conserves resources, ensuring long-term environmental responsibility.

▼

Digital twins simulate and optimize manufacturing processes, predict equipment failures, and provide a virtual training environment. This leads to streamlined operations and reduced downtime.

Conclusion

The automotive industry is undergoing a significant transformation driven by a wave of technological innovations. These advancements are not only enhancing production efficiency but also promoting sustainability and customization. As these technologies continue to evolve, they promise to further revolutionize how cars are designed, manufactured, and brought to market, ensuring a more efficient, sustainable, and customer-centric future.